Introduction to L Sealer Machines

An L Sealer Machine is a pivotal piece of equipment in the packaging industry, designed to efficiently seal products within a protective film. Its name is derived from its distinctive L-shaped sealing bar, a critical component responsible for creating secure and uniform seals. This machine operates by utilizing a combination of heat and pressure to seal the edges of a shrink film around a product or a group of products. The process not only safeguards items from external elements, but also provides a clean and professional finish. This method of packaging is highly versatile and is commonly employed across various industries, including food and beverage, pharmaceuticals, retail, and manufacturing. Read further to explore the different types of L Sealer Machines.

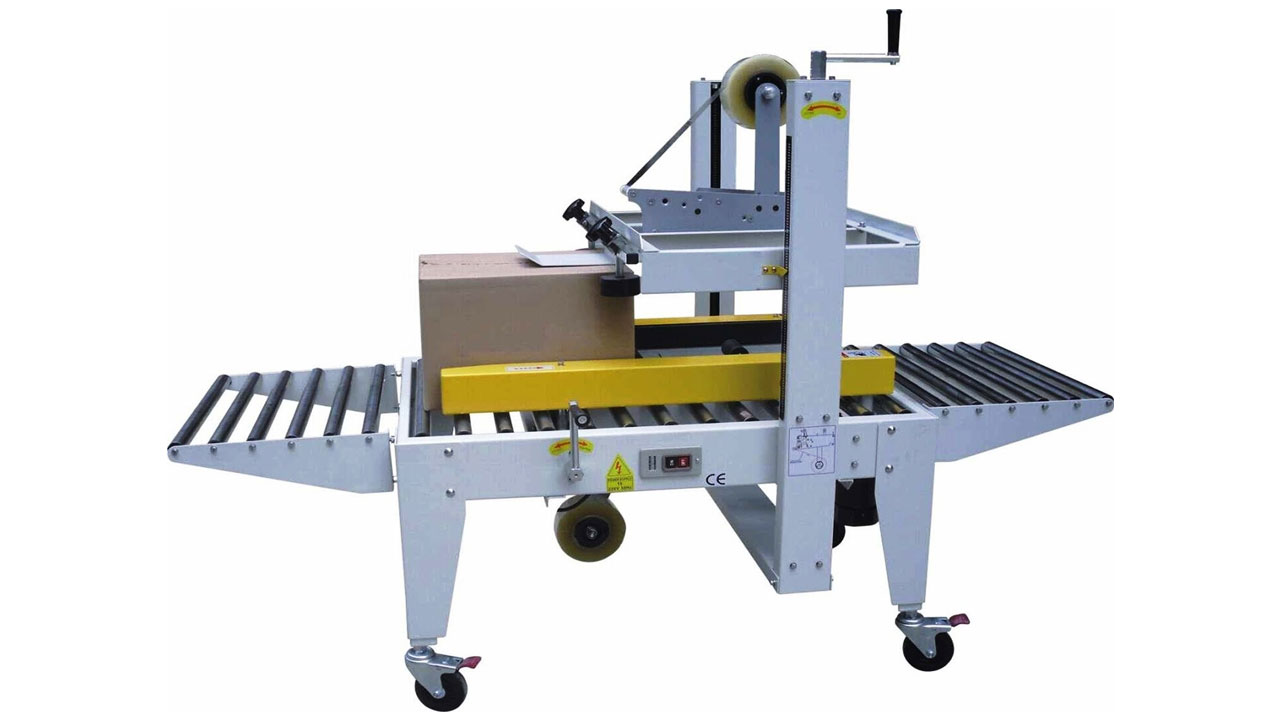

Revolutionizing Packaging Efficiency: The Power of Automatic L Sealer Machines

An automatic L Sealer Machine represents the pinnacle of packaging efficiency and automation. This specialized equipment is designed to streamline the packaging process, making it ideal for businesses with high-volume production needs. Unlike manual or semi-automatic models, an automatic L Sealer Machine operates with minimal human intervention, maximizing output and reducing labour costs.

The operation of an automatic L Sealer Machine is characterized by its seamless integration of various components. Once the product or products are placed on the packaging line, the machine’s conveyor system transports them to the sealing area. Here, the L-shaped sealing bar is automatically engaged, applying the necessary heat and pressure to create a precise, airtight seal around the products. Simultaneously, the excess film is trimmed away, leaving a neatly packaged product ready for distribution.

One of the key advantages of an automatic L Sealer Machine is its remarkable speed and consistency. With the ability to process a high volume of products in a short amount of time, businesses can achieve substantial gains in production efficiency. Additionally, the automated operation reduces the risk of human error, ensuring that each package is sealed with the same level of precision and quality.

In industries where speed, precision, and high throughput are paramount, such as e-commerce fulfilment centers, food processing plants, and manufacturing facilities, an automatic L Sealer Machine is an invaluable asset. Its ability to seamlessly integrate into existing production lines, coupled with its exceptional performance, makes it a cornerstone of modern packaging operations. By investing in an automatic L Sealer Machine, businesses can unlock a new level of efficiency and productivity in their packaging processes.

Mastering Precision Packaging: The Art of Manual L Sealer Machines

Manual L Sealer Machine represents a fundamental tool in the realm of packaging. Unlike its automated counterparts, this type of machine requires a more hands-on approach from operators. Manual L Sealers are typically chosen for operations with lower production volumes or when a higher degree of control and customization is desired in the packaging process.

Operating a manual L Sealer Machine involves a series of straightforward steps. After placing the product or products within the shrink film, the operator manually lowers the L-shaped sealing bar onto the film. This action initiates the application of heat and pressure, which creates a secure and tight seal around the items. Subsequently, any excess film is manually trimmed away, leaving a neatly wrapped product ready for distribution.

One of the primary benefits of using a manual L Sealer Machine is the level of control it affords. Operators can precisely adjust the sealing process to accommodate various product sizes and types of shrink film. This flexibility is particularly advantageous for businesses with diverse packaging needs.

While manual L Sealer Machines may not offer the same level of speed and efficiency as automatic models, they excel in situations where customization and attention to detail are paramount. They are often favoured in industries such as artisanal manufacturing, boutique retail, and specialized packaging where a personal touch and meticulous packaging presentation are highly valued.

Ultimately, the choice between a manual and automatic L Sealer Machine hinges on the specific requirements of the business. For those seeking a balance between control, affordability, and customization in their packaging process, a manual L Sealer Machine remains an indispensable tool.

Sealing Excellence: L Sealer with Shrink Tunnel Machines Unveiled

The combination of an L Sealer with a Shrink Tunnel Machine represents a powerful packaging solution that ensures both efficiency and a polished final product. This integrated system is widely used across various industries for its ability to provide a secure seal around products and then evenly apply heat for shrink wrapping.

The process begins with the L Sealer Machine, where the product or products are placed within the shrink film. The L-shaped sealing bar then creates a precise seal around the items. Next, the products are transported through the Shrink Tunnel. This tunnel generates controlled heat, causing the shrink film to uniformly tighten around the items, creating a tight and professional finish.

The synergy between the L Sealer and Shrink Tunnel offers several advantages. Firstly, it significantly speeds up the packaging process compared to manual methods. This combination allows for a seamless, continuous workflow, which is crucial for high-volume production environments. Additionally, the use of a Shrink Tunnel ensures that the shrink film conforms tightly to the shape of the products, resulting in a clean, wrinkle-free finish.

In industries such as manufacturing, retail, and e-commerce, where presentation and efficiency are paramount, an L Sealer with Shrink Tunnel Machine is an invaluable asset. It not only enhances the visual appeal of products but also provides a secure packaging solution. By investing in this integrated system, businesses can elevate their packaging process, ensuring that products reach customers in pristine condition, all while optimizing production efficiency.

Optimizing Efficiency: Sharp Engineering’s Cutting-Edge L Sealer Machine

In the fast-paced world of modern packaging, Sharp Engineering’s cutting-edge L Sealer Machine stands as a beacon of efficiency and innovation. With its advanced technology and meticulous craftsmanship, this machine exemplifies a commitment to streamlining operations and elevating the packaging process. By seamlessly integrating state-of-the-art features with user-friendly functionality, Sharp Engineering has crafted a tool that not only meets but exceeds the demands of today’s industries. The result is a packaging solution that not only ensures products are sealed securely, but also optimizes resource utilization, leading to a more sustainable and cost-effective approach.

Choose Sharp Engineering, choose efficiency, and embrace the future of packaging. Elevate your operations with a machine that’s not just state-of-the-art, but a game-changer in the world of packaging. Contact Us Today!