Understanding the Importance of Packaging Machines

Packaging machines play a pivotal role in today’s fast-paced industrial landscape, offering businesses a competitive edge through heightened efficiency and precision in the packaging process. Their significance cannot be overstated, as they serve as the linchpin between production and distribution phases. These machines streamline the packaging process, ensuring that products are securely and consistently packed, meeting quality standards and consumer expectations. Beyond the obvious benefits of speed and accuracy, packaging machines also contribute significantly to cost savings. By automating tasks that would otherwise require manual labour, businesses can allocate resources more strategically and reduce overhead expenses.

Moreover, these machines can adapt to various packaging materials, from plastics to glass and beyond, providing versatility in handling different product types. This adaptability not only broadens the scope of industries that can benefit from packaging machinery but also accommodates the diverse needs of manufacturers. In essence, packaging machines are the unsung heroes of modern production lines, enabling businesses to achieve higher volumes, lower costs, and enhanced product quality. Their role in maintaining the integrity and appeal of packaged goods is instrumental in building consumer trust and loyalty, making them a cornerstone of successful operations across industries worldwide. So let’s delve into the different types of Packaging Machines for different applications.

Bag Sealing Machines: Ensuring Freshness and Security in Packaging

Bag Sealing Machine is a vital component in the packaging industry, specifically designed to securely seal various types of bags and pouches. This type of packaging machine is particularly crucial in industries where products need to be stored or transported in airtight conditions to maintain freshness and quality. Continuous band sealers are designed for high-volume operations, providing a continuous and uniform seal along the bag’s opening. They are highly efficient and are commonly employed in industries with large-scale packaging requirements, such as food production or pharmaceuticals.

Bag sealing machines play a crucial role in ensuring the integrity and quality of packaged goods. They help extend the shelf life of products, prevent contamination, and maintain freshness. Additionally, these machines enhance operational efficiency by automating the sealing process, reducing the need for manual labour. This not only increases productivity but also minimizes the risk of human error. In essence, bag sealing machines are indispensable tools for businesses aiming to optimize their packaging processes while ensuring the utmost quality and safety of their products.

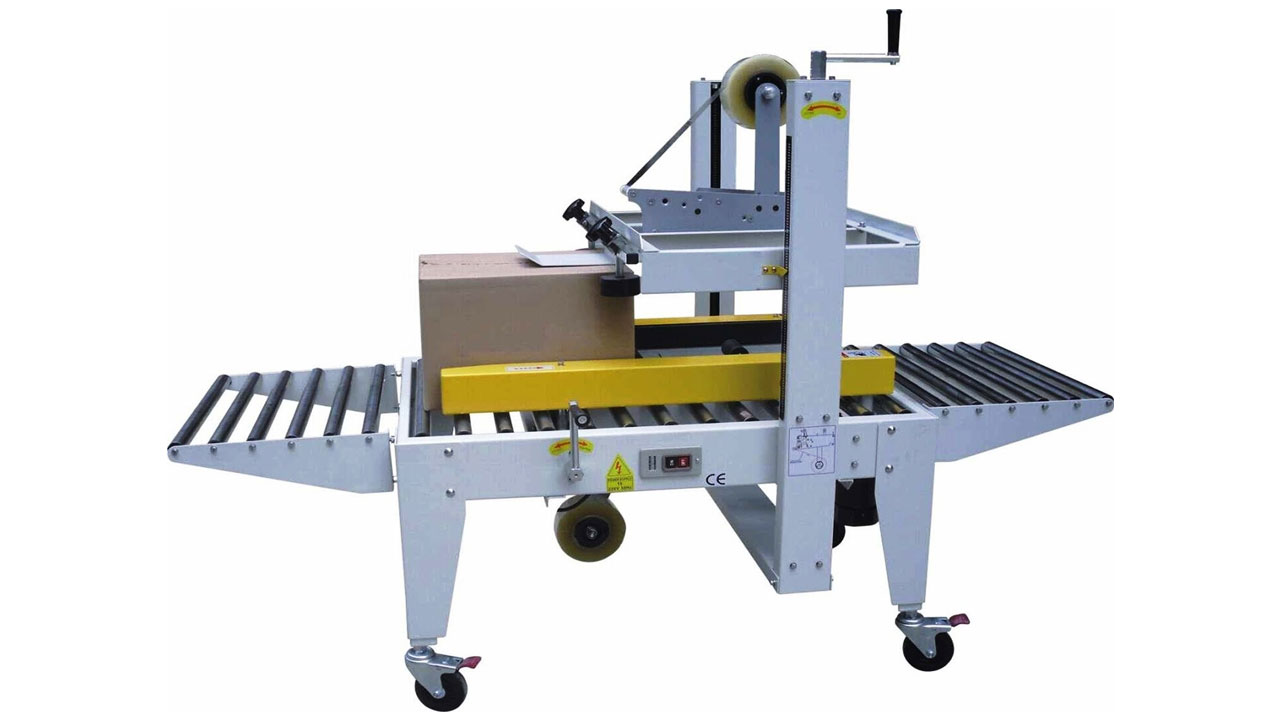

Efficient Carton Sealer Machines: Streamlining Packaging Operations

Carton sealer machines are a fundamental component of packaging lines, designed to automate and enhance the process of sealing cartons and boxes. These machines are essential for industries that handle large volumes of packaged goods, such as warehouses, distribution centers, and manufacturing facilities.

Carton sealer machines are a cornerstone of efficient packaging operations, ensuring that goods are securely sealed and ready for distribution. By automating this crucial step, businesses can achieve higher levels of productivity, reduce costs, and maintain a consistent level of quality in their packaged products. Investing in the right carton sealer machine is a strategic move that can have a significant impact on the overall efficiency and success of your packaging operations.

Optimizing Packaging Efficiency with Fully Automated Strapping Machines

Fully automated strapping machines revolutionize the way businesses secure and bundle packages for shipping and storage. These advanced machines are a cornerstone of modern packaging operations, offering a high level of efficiency, consistency, and reliability. Fully automated strapping machines, also known as automatic banding machines, are designed to securely strap bundles or packages with a high degree of precision. They excel in high-volume operations where speed and accuracy are paramount.

Fully automated strapping machines are a game-changer in the packaging industry, offering businesses the ability to secure packages quickly, efficiently, and with precision. By investing in this advanced technology, companies can significantly enhance their packaging processes, leading to higher productivity, cost savings, and ultimately, greater customer satisfaction.

Seal with Precision: Unveiling the Power of L Sealer Machines

L sealer machines are a fundamental component in the packaging industry, renowned for their ability to create precise and secure seals around products. These machines are widely used in various industries, including food, electronics, and retail, where professional packaging is crucial. An L sealer machine is a packaging device designed to create a sealed package by wrapping a product in a shrink film. It operates by forming an “L” shape around the product and applying heat to the film, creating a tight and protective seal.

L sealer machines are a cornerstone of efficient and professional packaging operations. By investing in this technology, businesses can ensure that their products are securely and attractively packaged, leaving a positive impression on consumers. The precision, versatility, and speed offered by L sealer machines make them an invaluable asset for businesses looking to elevate their packaging processes to the next level.

Efficient Packaging with Semi-Automatic Strapping Machines

Semi-automatic strapping machines represent a crucial bridge between manual and fully automated packaging processes. These versatile machines offer businesses an efficient and cost-effective solution for securely bundling and strapping packages. Semi-automatic strapping machines are designed to streamline the strapping process without the need for full automation. They strike a balance between manual strapping, which can be time-consuming, and fully automated systems, providing an efficient compromise.

Semi-automatic strapping machines are a versatile and cost-effective solution for businesses looking to optimize their packaging processes. By striking a balance between manual and fully automated methods, they offer an efficient way to secure packages for shipping and storage. When selected and operated with consideration, these machines can significantly enhance the overall efficiency and productivity of packaging operations.

Sealing Perfection: Unveiling the Power of Shrink Packing Machines

Shrink packing machines have emerged as indispensable tools in the world of packaging, offering a highly effective and visually appealing way to encase products. These machines utilize heat and specialized shrink film to create a secure and snug packaging for a wide range of items. Shrink packing machines operate on a straightforward yet highly effective principle. They use heat to shrink specialized film around a product, creating a tight and protective wrap. This process not only secures the product but also enhances its presentation.

Shrink packing machines represent a powerful solution for businesses seeking to enhance the protection and presentation of their products. With their efficiency, versatility, and visually appealing results, they have become a cornerstone in modern packaging operations across various industries. By selecting the right machine and film type for specific products, businesses can elevate their packaging processes to a new level of efficiency and professionalism.

Efficiency in Your Hands: Unveiling the Power of Strapping Hand Tools

Strapping hand tools are essential devices in the world of packaging, providing a manual yet highly effective method for securing packages and bundles. These tools offer versatility and control, making them indispensable in various industries. Strapping hand tools are manually operated devices designed to tension, seal, and cut strapping material. They are ideal for situations where a high degree of control and precision is required in the strapping process.

Strapping hand tools put the power of efficient packaging in the hands of operators. With their portability, versatility, and cost-effectiveness, they are a valuable asset in various industries. By selecting the right tool for specific strapping needs, businesses can enhance their packaging processes and ensure the secure transit and storage of their products.

Efficient Packaging Solutions: The Impact of Stretch Wrapping Machines

Stretch wrapping machines have revolutionized the way products are secured and prepared for transit or storage. These versatile machines use stretch film to tightly wrap and protect a wide range of products, offering benefits across industries. Stretch wrapping machines are automated devices designed to apply stretch film around a product or load. This process creates a secure, protective barrier that helps stabilize the load during transport and safeguard it from external elements.

Stretch wrapping machines are pivotal in enhancing packaging efficiency and protecting products during transit and storage. With their adaptability, load stability, and cost-effective stretch film usage, they have become an integral part of modern packaging operations. By selecting the right machine for specific load sizes and operational needs, businesses can optimize their packaging processes and ultimately improve their supply chain efficiency.

Elevate Your Packaging Operations with Sharp Engineering’s Innovative Machines

The world of packaging has been revolutionized by the advent of advanced machinery, and Sharp Engineering stands at the forefront of this innovation. With a dedicated focus on manufacturing and supplying a diverse range of packaging machines, we’ve established ourselves as leaders in the industry. Our machines, meticulously designed and crafted, excel in various critical packaging applications, including strapping, sealing, wrapping, and shrink packing. What sets us apart is our unwavering commitment to tailoring solutions to meet the unique needs of different industries. Whether it’s the fast-paced demands of manufacturing or the precision required in logistics, our machines rise to the occasion, ensuring seamless and efficient packaging operations.

As we continue to push boundaries in engineering excellence, our mission remains clear: to provide businesses across sectors with cutting-edge packaging solutions that not only enhance operational efficiency but also safeguard the integrity and presentation of their products. Partner with us, and experience first-hand how Sharp Engineering’s expertise and technology can elevate your packaging processes to new heights. Together, we pave the way for a future where packaging is not just a necessity, but a strategic advantage. Contact Us Today!